SOLUTIONS & PRODUCTS

Products

BUY | QUOTE

BUY | QUOTE

English

International

BUY | QUOTE

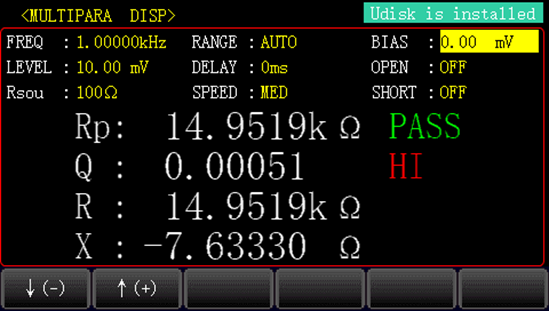

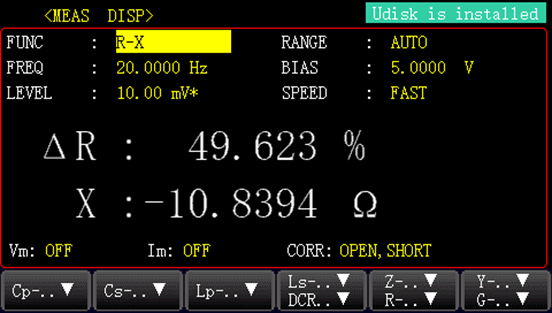

The quality factor Q of an inductor indicates how close the device approaches pure reactance; the larger the quality factor, the greater the absolute value of the reactance.

For capacitor, this item indicating purity is usually expressed by the dissipation factor D, D=1/Q; therefore the smaller the D, the higher the capacitive reactance and the better the efficiency.

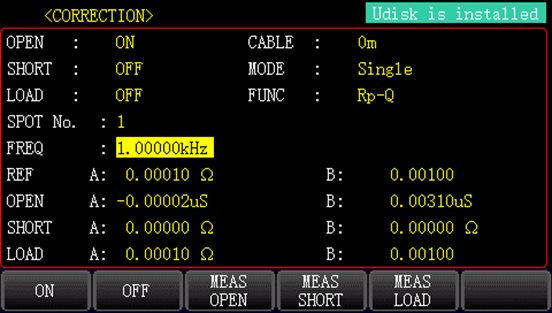

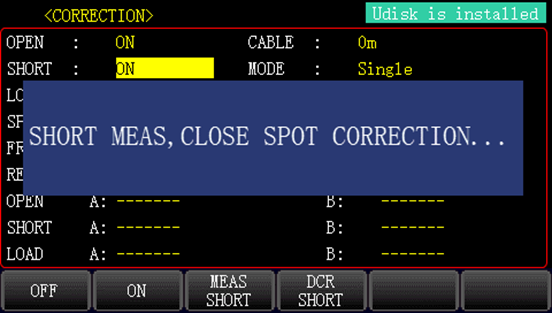

Has short circuit and open circuit zeroing been performed?

Confirm that short-circuit (for resistance) and open-circuit (for capacitance and inductance) compensation procedures have been correctly performed before testing.

Is the device under test a known standard source?

Ensure that the component being measured is a calibrated standard or a known reference. Using uncalibrated or damaged components as references can lead to inaccurate assumptions about error.

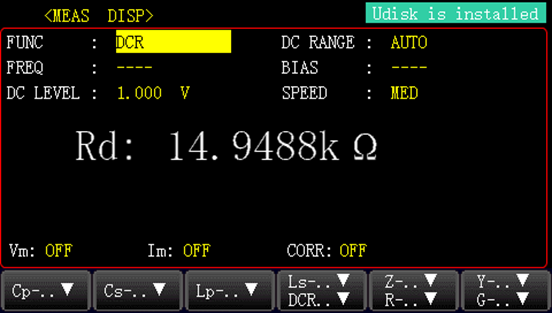

Is the range set to AUTO?

Check if the meter is set to AUTO range mode. In some cases, manually selecting the correct measurement range improves accuracy and stability.

1. Connect the wire of the Handler to supply power to the Handler.

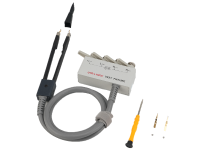

2. Connect the adapter of UTR-S100KE to the front panel of the LCR meter.

3. Perform zeroing calibration on the LCR meter.

4. Set the parameters of the electronic components to be measured, and set the trigger mode to external trigger.

5. Insert electronic components for testing, and the test results will be displayed on the screen.

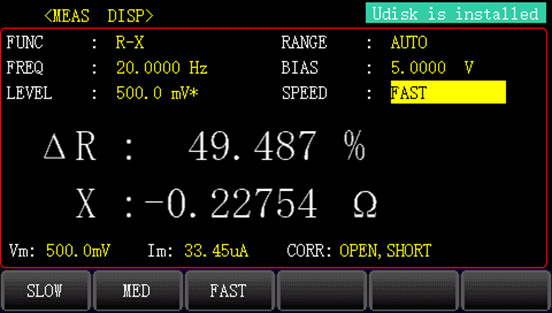

1. There was a reverse connection during the testing of the test clip

2. The testing frequency is too high (the fundamental frequency of the electrolytic capacitor is as low as 120Hz or 1Khz)

3. Select test mode: electrolytic capacitors are suitable for parallel connection Cp